When 3D printers from Makerbot made their way out of the laboratories and onto store shelves, I braced myself for the hype. Sure enough, stories from across the Internet quickly began to talk about 3D printers as though they were just a few weeks from becoming standard household appliances. But before companies start investing time and money in preparing elaborate strategies around this admittedly cool technology, let’s get a few things straight. Consider this a much needed reality check.

The 3D printing fantasy usually goes like this: Soon everyone will have a 3D printer in their kitchens or laundry rooms, and they will be able to just download anything they want off the Internet and print it. This will create tremendous opportunities for users and the brands trying to reach them – a new and decidedly different user experience. Stuff like printing a product right into your living room. I’ve heard predictions that within 3-5 years this will be possible. I can tell you from experience that this is ridiculous.

Look at the first desktop printers in the mid 1980’s. It’s easy to forget that, in the early days, setting up a printer to work properly was a nightmare. Fast forward to the present day – you can connect to a printer with the simple click of a button. But when you add the dimensionality and durability essential to 3D printing, you can see how complicated things can get.

SEE ALSO: Branding Is Not a Popularity Contest

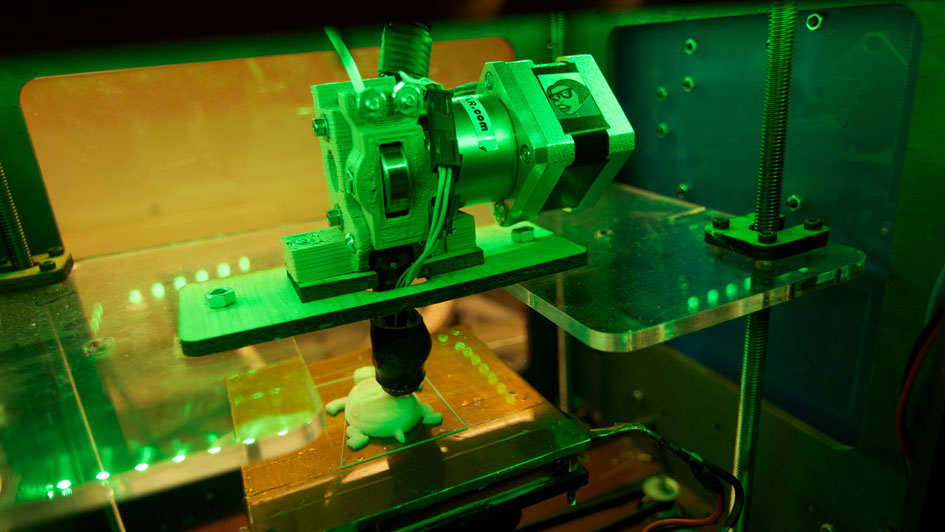

The truth is that 3D printers are still incredibly sophisticated machines. You need the time and patience to understand how these printers work, the knowledge on how to tweak them and the experience to know what things can be printed and what cannot. These skills take an industrial designer who can model in a 3D application, along with a creative technologist to help with the hardware and software side of the printer. Of course, 3D printers are versatile in the right hands, enabling experts to create everything from guns to prosthetic hands; however, in terms of their limitations, there’s still a long way to go.

Size, for example, is a big issue in my mind. Right now, on a Makerbot Replicator 2, you can only print something that is relatively small – roughly 1 foot long, 6-8 inches deep and about 10 inches high. Also, while there are new printers that can print using metals and other materials like Kevlar, most consumer grade printers can only print plastic. By contrast, look at the average home product – or any product for that matter. Most of these everyday objects get their particular look, durability and strength from a variety of materials. Consumers expect a certain brand and product consistency that 3D printing can’t yet provide.

For brands and agencies looking to enter the 3D printing game, I’d like to propose a new, less sensationalized 3D printing fantasy: The true value of 3D printing will come from more efficient production models resulting in lower prices, quicker turnaround times and more innovative branding concepts. Our industry is completing more projects, spanning greater form factors than ever before – creating installations, commercials and interactive experiences that live in the real world as well as the digital world. Companies need the ability to rapidly prototype these ideas, whether it’s a visual, an application or even robot bodies that house electronics.

SEE ALSO: Pizza Hut Showcases the Future of Restaurant Dining

This is where rapid prototyping becomes a necessity. Instead of waiting weeks for production of an element – print it in an afternoon, iterate a second version by nighttime and have a working prototype in a few days. Having 3D printing capabilities can enable any company to take on complex projects, and finally allow the advertising and branding industries to catch up to the lightning-fast needs of the Internet age. It also gives our industry the opportunity to approach problems from a less traditional point of view.

For brands and agencies, the future of 3D printers is not about putting the new technology into every home, but about giving one to a team of the right people and letting them experiment. They’ll learn from each project, and create new approaches to old ideas. With a little time, maybe they’ll push the technology forward and produce something that will give us a real reason to put a 3D printer in every home.

Just don’t expect your mom to start 3D printing anytime soon.

Photo: kakissel